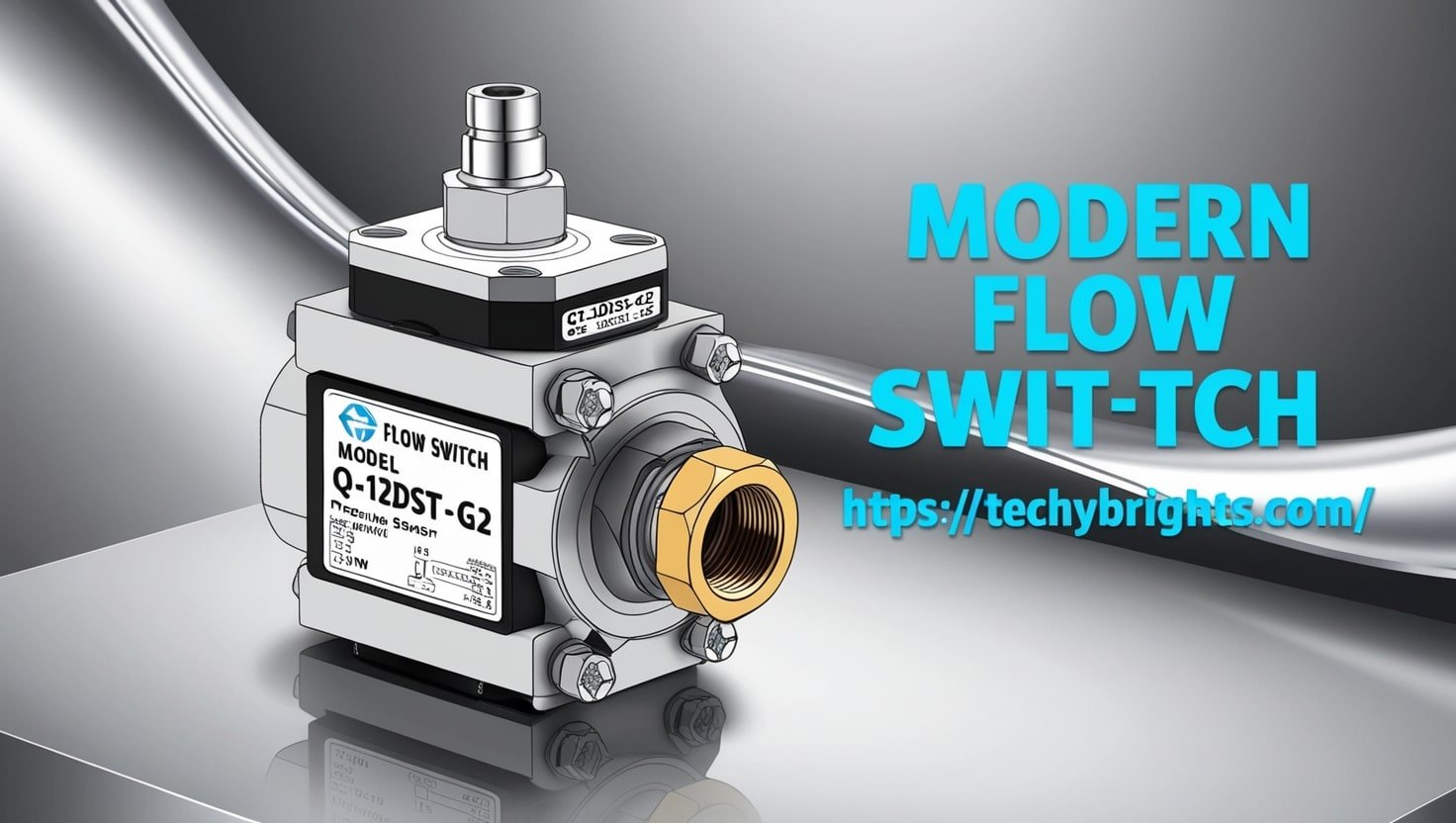

Flow switches are essential components used in a wide range of industrial applications to monitor and control fluid flow within a system. Among the various flow switch models available, the flow switch model Q-12DST-G2 stands out for its reliability, efficiency, and ease of use. In this article, we will explore the significance of this specific model, its features, applications, and the reasons why it has become a popular choice among engineers and technicians.

What is a Flow Switch?

A flow switch is a device that monitors the flow rate of a fluid in a system and triggers an action when the flow exceeds or falls below a certain threshold. These devices are widely used in systems that rely on consistent fluid flow, such as cooling systems, water treatment plants, and HVAC systems. Flow switches can activate alarms, pumps, or shut down systems to prevent damage or inefficiency due to abnormal flow conditions.

The flow switch model Q-12DST-G2 is a particularly versatile and robust model that provides excellent performance in a variety of industrial settings. It is designed to offer precise flow measurement while maintaining durability and ease of maintenance.

The Importance of Accurate Flow Measurement

In any fluid-based system, it is essential to ensure that the flow remains within specified limits. If the flow rate is too low, it can lead to inadequate cooling, inefficient operation, or even system failure. Conversely, excessive flow can result in equipment damage, increased energy consumption, or safety hazards.

The flow switch model Q-12DST-G2 plays a vital role in maintaining optimal flow conditions by providing accurate and reliable measurements. By constantly monitoring the flow rate, it helps prevent these issues, ensuring that systems operate smoothly and efficiently.

How the Flow Switch Model Q-12DST-G2 Works

The flow switch model Q-12DST-G2 operates based on a mechanical or electronic sensing element that detects changes in the fluid’s flow rate. When the flow rate crosses a preset threshold, the switch activates and triggers a response, such as an alarm or system shutoff. This ensures that the system is protected from abnormal flow conditions that could cause damage or inefficiency.

Depending on the specific configuration of the flow switch model Q-12DST-G2, it may feature adjustable set points, allowing users to fine-tune the flow rate at which the switch activates. This flexibility is crucial for systems with varying flow conditions or where precise control is required.

Flow Switch Model Q-12DST-G2: A Deeper Dive into Its Design and Engineering

The flow switch model Q-12DST-G2 stands out not only for its operational capabilities but also for its impressive design and engineering. Understanding its design is crucial for technicians and engineers who are looking to integrate it into complex systems. This flow switch is built to meet the demands of a variety of industries, making it a reliable and efficient solution for fluid monitoring.

One of the primary elements of the flow switch model Q-12DST-G2 is its robust housing. The materials used in its construction are selected for their durability and resistance to environmental stress. Whether installed in a high-temperature environment, an area with fluctuating pressure, or a corrosive chemical environment, the Q-12DST-G2 is designed to hold up over time. Its housing is often made from corrosion-resistant metals or high-strength polymers, ensuring that it can withstand tough industrial conditions.

Additionally, the design of the flow switch model Q-12DST-G2 includes features that make installation and maintenance easier. The device is typically lightweight and compact, allowing it to be installed in tight spaces without compromising its functionality. Whether you’re retrofitting an older system or adding it to a new setup, the Q-12DST-G2 is flexible and adaptable, making the installation process straightforward for operators.

Integration and Compatibility with Existing Systems

One of the significant advantages of the flow switch model Q-12DST-G2 is its compatibility with a wide variety of existing systems. Whether you’re working with a simple water pump or a complex industrial process, this flow switch model is designed to integrate seamlessly with many different types of equipment.

The flow switch model Q-12DST-G2 typically comes with standardized connectors and wiring options, which makes it easy to connect to control systems, alarms, and other devices that are part of your system. Its interface is often designed to be intuitive, meaning you don’t need specialized tools or training to make adjustments or troubleshoot issues.

This compatibility with existing systems is essential for minimizing downtime during installation or upgrades. As industries continue to modernize and integrate newer technologies, the flow switch model Q-12DST-G2 offers flexibility, allowing you to take advantage of improved flow monitoring without the need for a complete system overhaul.

Environmental Considerations for the Flow Switch Model Q-12DST-G2

Environmental factors play a crucial role in the performance of any industrial device, and the flow switch model Q-12DST-G2 is no exception. When choosing a flow switch for your system, it is essential to consider the environment in which it will be operating, as this can impact its longevity and reliability.

The flow switch model Q-12DST-G2 is designed with environmental considerations in mind. Its weather-resistant features ensure that it can operate effectively even in outdoor conditions or areas with significant temperature fluctuations. This is particularly important for industries like water treatment, where flow switches are exposed to varying environmental conditions.

Additionally, some versions of the flow switch model Q-12DST-G2 are designed to be environmentally friendly, using non-toxic materials and energy-efficient technology. This commitment to sustainability not only helps reduce the environmental impact of operations but also ensures that the device adheres to global environmental standards.

Troubleshooting and Maintenance of the Flow Switch Model Q-12DST-G2

While the flow switch model Q-12DST-G2 is known for its reliability, like any mechanical or electronic device, it may require occasional maintenance or troubleshooting. Fortunately, the design of the Q-12DST-G2 makes it relatively easy to maintain, ensuring that your system remains operational without requiring excessive downtime.

A key maintenance step involves regularly inspecting the device for wear and tear. Over time, debris or buildup may clog the sensor or switch mechanism, which can affect its accuracy. Routine cleaning is essential to ensure that the flow switch model Q-12DST-G2 continues to perform optimally. This can typically be done with basic tools, without requiring the flow switch to be removed from the system.

Customization Options for the Flow Switch Model Q-12DST-G2

The flow switch model Q-12DST-G2 offers various customization options, allowing businesses to tailor its features to meet specific needs. Whether your application requires a particular flow range, a certain pressure rating, or unique mounting options, the flexibility of the Q-12DST-G2 ensures that it can be configured to suit a wide array of industrial applications.

For example, depending on your system’s requirements, you can adjust the set points of the flow switch model Q-12DST-G2 to trigger an alert or shutdown at specific flow thresholds. This customization ensures that the flow switch aligns with the unique operating conditions of your system.

Moreover, the flow switch model Q-12DST-G2 comes with various connection options, making it easy to integrate with existing piping and control systems. This adaptability is particularly useful for businesses that may be retrofitting older systems or integrating new technologies without requiring an entirely new setup. By offering a high degree of customization, the Q-12DST-G2 can be seamlessly incorporated into a wide variety of industrial setups.

The Cost-Effectiveness of the Flow Switch Model Q-12DST-G2

In today’s competitive business environment, cost-effectiveness is a significant factor when choosing industrial components. The flow switch model Q-12DST-G2 offers excellent value for money while delivering top-tier performance. Its long lifespan, low maintenance requirements, and ability to prevent costly system failures make it an economically sound investment for companies seeking reliable flow monitoring solutions.

When compared to other flow switches in the market, the flow switch model Q-12DST-G2 offers a competitive price point without sacrificing quality. Its durable construction and advanced features ensure that you get more value out of your investment, reducing the need for frequent repairs or replacements. In many cases, the flow switch model Q-12DST-G2 can pay for itself over time by preventing costly failures and minimizing downtime.

Additionally, the flow switch model Q-12DST-G2 contributes to energy savings. By ensuring that flow conditions remain optimal, it helps systems operate more efficiently, which reduces energy consumption. In industries where energy costs are a significant part of the operational budget, the Q-12DST-G2’s role in improving system efficiency can lead to substantial savings over time.

The Global Reach of the Flow Switch Model Q-12DST-G2

The flow switch model Q-12DST-G2 is used around the world in various industries and applications, from manufacturing plants in North America to water treatment facilities in Europe and chemical processing plants in Asia. Its global reach can be attributed to its versatility, high performance, and ability to meet international standards for safety and quality.

For businesses that operate across multiple regions or that source equipment from different parts of the world, the flow switch model Q-12DST-G2 provides a uniform solution. Its standardized design and global availability mean that companies can rely on the same high-quality product regardless of location. This consistency helps streamline operations and ensures that businesses can maintain the same level of reliability and performance in different countries.

Conclusion:

In conclusion, the flow switch model Q-12DST-G2 is an exceptional device that combines precision, durability, and ease of use. Whether you’re working in a manufacturing plant, a water treatment facility, or a chemical processing plant, this flow switch provides a reliable solution to monitor and control fluid flow. Its comprehensive design, compatibility with various systems, and adaptability to different environments make it an essential tool for industrial applications.

The flow switch model Q-12DST-G2 not only ensures the safe operation of systems by detecting abnormal flow conditions but also helps improve efficiency and reduce maintenance costs. It serves as a safeguard against the risks associated with inconsistent flow rates, contributing to the longevity of your equipment and the overall effectiveness of your processes.